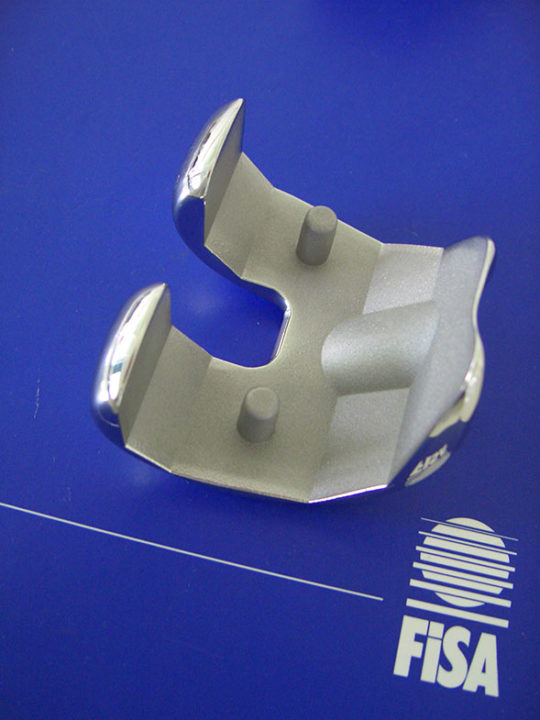

The medical market: mainly in orthopedics or dentistry

ssssOur main customers in the medical field are implant manufacturers, mostly major international companies in the orthopedics or dentistry.

We also have references among manufacturers of stents, pacemakers, defibrillators, probes, parietal implants, etc. (…)

Cleaning any type of component implanted in the human body

Generally speaking, we clean any type of component implanted in the human body. As you can imagine, the cleanliness standards are very high for this type of part.

We also work with suppliers of non-implantable medical devices, especially those used in clinics or hospitals.

In particular, I am thinking about ancillary equipment for orthopedics or other surgical procedures, such as scalpels, scissors and other instruments.

Our customers include big names such as Stryker, Medtronic, Johnson & Johnson, Zimmer, etc.

We clean any type of component implanted in the human body

Are there lines of machines specially designed for the medical industry? How do they differ from others?

Our machines have been designed to be appropriate to different business areas.

Our approaches and ways of designing machines mean that their construction will differ depending on the stage we have reached in the medical project.

If we are at the beginning of manufacturing – such as making a part – there will be mainly mechanical marks (related to polishing pastes, oils, etc.).

So, we’ll offer machines designed to meet these needs.

In general, the closer we get to final cleaning – i.e. the last cleaning step before packaging in the cleanroom – the more specific our machines will be.

In particular, we have machines with a very special tank design for final cleaning; we use it in other sectors such as optics, watchmaking or high-tech mechanics.

These machines are also used in the pharmaceutical sector.

How are your machines designed for the medical sector? Do these machines have technical differences or special features?

We use a three-grade approach to determine the characteristics of the machine based on the cleaning phase and the customer’s profile.

Each grade has its own special design with specific technical characteristics.

You have the first grade that covers optical, watchmaking, medical or micro-technical companies.

The second grade only involves implant manufacturers, while the third grade covers aerospace but also the pharmaceutical sector.

Machines with sanitary capability

The third grade has particularly demanding requirements, so we have to design machines with sanitary capability.

In the event of microbial contamination, it must be possible to decontaminate and remove all dirt without the need for disassembly.

This naturally requires special design.

- As an example, if we take the shape of tanks, we’re going to make them curve so that liquid retention is impossible.

- Turning to fittings for hydraulic connections, we move away from union fittings to use what are known as “clamp” technology fittings.

- When welding, we will use what we call orbital welds with roughness checks and we can also choose to use specific materials.

We have to design machines with sanitary capability

At Fisa, we can meet all these requirements, we can modify the technical characteristics of our machines, given that 80% of our orders fall within the scope of our “first grade”, 15% on the second and 5% on the third grade.

And when it comes to installing of our machines, we follow very precise protocols, especially for users in the medical sector. In particular, we have to document the installation phase thoroughly to ensure that during an audit or inspection, our customers can provide all the necessary evidence and documents.

Will a grade 3 machine take longer to design? Will it also be more expensive than a grade 1 or 2 machine?

In design terms, it makes little difference. We have full control of our manufacturing facilities so we can design them quite quickly even with demanding requirements.

However, the size of the machine and its dimensions can affect the length of the project.

Design may also take longer if we have to meet special requirements when selecting components.

We sometimes have customers who want specific components or components available in a particular country. In this case, we have to source the appropriate components and confirm they meet the requirements, etc.

For the cost of the machine, obviously a grade 3 machine requires more investment than a grade 1 machine. In general, the more demanding the requirements, the more specific its design and the more expensive it will be. The difference in cost can range from 1 to 6-fold, depending on our customers’ requirements.

The more demanding the requirements, the more specific its design and the more expensive it will be

Do medical users always know what they want when it comes to cleaning? Do you advise them on the cleaning methods to use?

It depends on the customers.

We have to distinguish between major users, in the market for a long time, and smaller companies that are just starting up.

In general, large groups know exactly what they want and submit very precise specifications that we have to follow to the letter.

In this case, we are content to meet these specifications, which does not prevent us from suggesting different solutions to meet their requirements.

For newcomers or medium-sized companies, we advise and guide them in the choice of machines to be used.

We have extensive experience in the subject and we’re delighted to share it with them. Of course, we draw particular inspiration from previous work done with the major users mentioned above

Other than sales revenues, what have your customers in the medical sector brought you?

In particular, the medical market has enabled us to improve our procedures. Procedures in the medical sector are well thought out and it can be used in other sectors.

Moreover, other users are increasingly inspired by these methods. When I talk about procedures, I think particularly of qualification processes, such as for an installation following the IQ/OQ/PQ protocol.

FISA, 19 marca 2020