Designer and manufacturer of ultrasonic cleaning machines for all business activities, all markets, all industrial fields

Different fields, different problems, a single expert: FISA!

Markets we serve

For each market we understand the problems that you face. We will offer you the ultrasonic cleaning solution to meet your needs.

FISA works together with experts from many industrial fields to treat all types of contamination on all materials and surfaces. This collaboration is based on their individual specifications or on a functional statement of their needs.

For each market we understand the problems that you face.

We will offer you the ultrasonic cleaning solution to meet your needs.

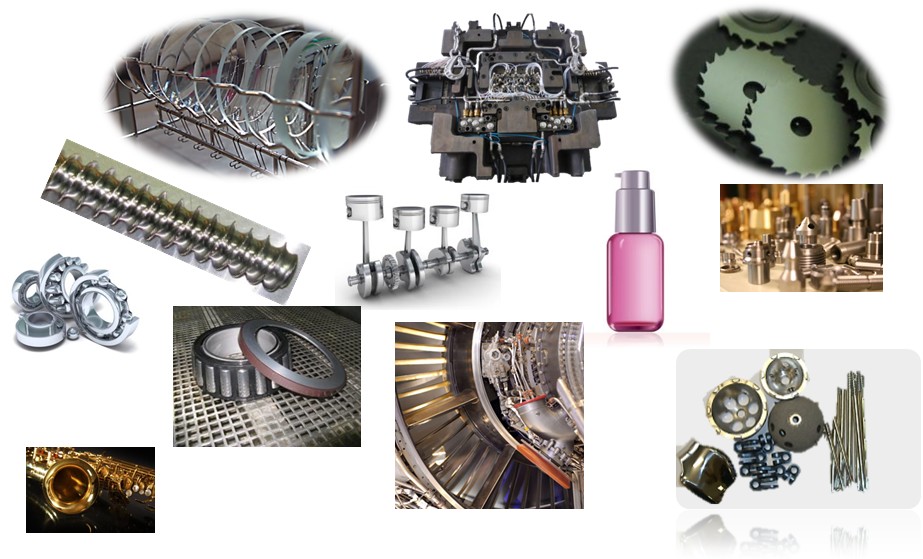

Limitless fields of activity: aerospace, foundry, watchmaking, jewelry, mechanics, medicine, optics, plastics and rubber processing, etc.

We have limitless fields of activity: from the moment you manufacture, when you use a production facility, we can offer you the right solution

- for cleaning your parts during production or finishing,

- for maintaining your molds and tools.

We do this, whatever your field of activity, whatever your field of application.

This solution will encompass:

- not only your technical constraints: type of materials, shape of your parts, fragility of your tools, etc.

- but also your production constraints: batch or continuous working, machine layout and user ergonomics, work under controlled atmosphere, water quality, etc.

- as well as your budgetary constraints.

Aerospace industry

FISA designs, manufactures and commissions ultrasonic cleaning facilities specifically for aerospace applications:

- optical or mechanical components after machining, grinding or assembly operations,

- components used for aerial navigation,

- …

Foundry: die-casting, low pressure, corebox

The ultrasonic cleaning process proposed by FISA offers the most benefits for maintaining your molds and tools, both technically and financially:

- casting of ferrous metals such as cast iron and steel

- non-ferrous metal foundry: copper, zinc and alloys

- light alloy foundry: aluminum, zamac and other light alloys

Watchmaking, Jewelry

For watch and jewelry businesses, the FISA ultrasonic cleaning process gives you an ideal aesthetic and mechanical result, whatever the shape of your parts, their materials and their contaminants.

Mechanics and Micromechanics

FISA has been perfecting the principles of water-based detergent cleaning processes for several decades. We can therefore offer you the most suitable solutions for cleaning manufactured mechanical parts along the whole production line.

Medical sector

You manufacture implants, instruments or tools needed to fit implants, hypodermic needles, syringes, etc. and you have many different cleaning requirements.

Specialists in cleaning for medical applications FISA’s expertise covers the specific technical constraints involved both before and after your business.

Optics

FISA offers a range of machines specifically designed for the following sectors:

- Ophthalmic optics

- Sun optics

- Safety optics

- Precision optics.

We cover all the needs of a production line.

Plastics and Rubber: Injection – Extrusion – Compression

FISA proposes the ultrasonic cleaning process offering the most advantages for maintaining molds and tools for businesses that inject thermoformable or thermoplastic materials and extrude plastics or rubber materials.

Other fields of activity

We have limitless fields of activity, so don’t hesitate to ask:

- food-processing industry,

- automobile,

- cosmetics,

- machining,

- railway,

- pharmaceutical industry,

- surface treatment,

- …